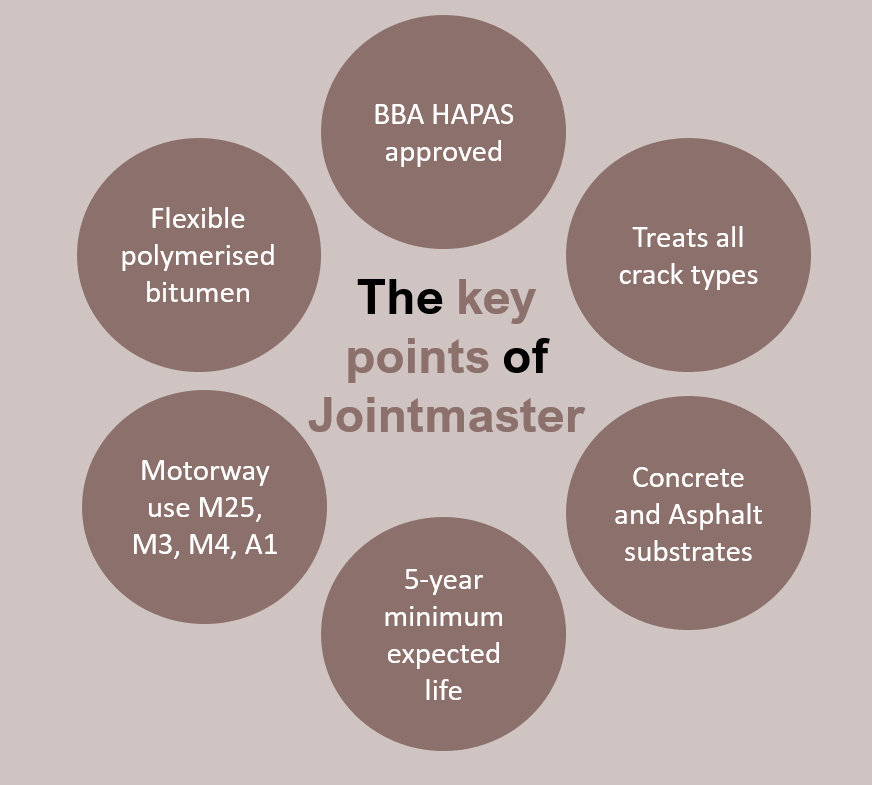

Jointmaster® – Flexible Crack & Joint Repair for Highways

Jointmaster® is a fully approved, high-performance system designed for repairing cracks, joints, and surface defects in both bituminous and concrete highway surfaces.

This specialist solution uses a flexible bituminous compound to reinstate failed areas—addressing the underlying cause of deterioration (typically movement) by accommodating expansion and contraction. Its elastic, durable nature ensures long-term performance and resistance to further cracking.

Whether for planned maintenance or reactive repairs, Jointmaster® delivers:

- Effective sealing of cracks and joints

- Long-lasting flexibility under load and thermal movement

- Fast application and minimal disruption

- Proven performance across UK highways

Ideal for:

- Asphalt cracking

- Concrete joint repair

- Surface defect reinstatement

- Prolonging pavement life

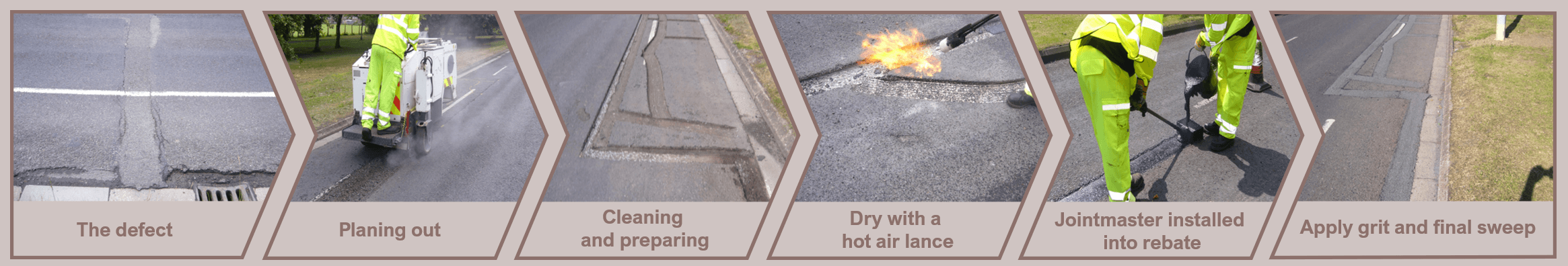

The Process:

Jointmaster® is a BBA-approved solution under the Highway Authorities Product Approval Scheme (HAPAS)—certified since 2007 as a flexible, long-term crack and joint repair system for highway surfaces.

Developed for durability, flexibility, and minimal disruption, Jointmaster® delivers proven performance across the UK’s road network, including:

Motorways

Trunk roads

Urban and rural carriageways

Housing estates and access roads

Proven performance and Benefits:

✅ Permanent, watertight seal using high-polymer, flexible bituminous materials

✅ Tested skid resistance, even after prolonged trafficking

✅ Rutting resistance under heavy loading (HGVs, buses, farm vehicles)

✅ Versatile application to asphalt, concrete, or overlaid concrete

✅ Fast application with minimal disruption—roads can reopen to traffic the same day

✅ No site closures overnight—repairs can be trafficked as soon as they’ve cooled

✅ Backed by decades of site experience and long-standing client relationships

With high output capability, Jointmaster® is ideal for reactive or planned programmes, allowing local authorities and contractors to reinstate failed surfacing quickly, reliably, and cost-effectively.

Jointmaster® – Daily Output & Productivity

Jointmaster® is designed for high-efficiency highway works, with output rates tailored to the type of treatment and site conditions. Typical daily outputs are:

Typical Daily Output Rates

Longitudinal recessed joints:

800–1,000 linear metres per dayTransverse joints:

300–400 linear metres per dayOverseal banding:

Up to 4,000 linear metres per dayRebated repairs:

Up to 1,000 linear metres per day

Site-Dependent Productivity

Actual output will vary depending on site layout, surface type, access restrictions, and weather conditions.

Higher outputs (e.g. motorway working) are achievable with additional crews and equipment.

Minimising disruption to Road Users

We understand the importance of keeping traffic moving. Jointmaster® is designed not just for long-term performance—but also for minimal disruption during installation.

Traffic Management Options

Our work can be safely delivered under a range of traffic control measures

- Lane closures

- Temporary Traffic Lights

- Road Closures

In most cases, single-file traffic can be maintained, reducing the need for full road closures and keeping public and local access routes open.

Flexible Working Hours:

We adapt to site and network demands:

• On urban roads, we can work during restricted daytime windows to suit local traffic flows

• On motorways and strategic routes, we typically operate under overnight lane closures

• Roads are reopened each morning, fully trafficable, with works resuming the following night if required

Our ability to deliver high-output repairs with minimal disruption makes Jointmaster® a trusted choice for highways teams across the UK.

M4 Longitudinal Seam Joints

8,000 Years of Engineering – Still Solving the Same Problem

It’s remarkable to think that bitumen is one of the oldest engineering materials known to man, used for more than 8,000 years. As early as 6,000 BC, the Sumerians were harnessing naturally occurring bitumen in a thriving shipbuilding industry. Even the Book of Genesis (11:1–4) records its use—as an adhesive jointing material during the construction of the Tower of Babel.

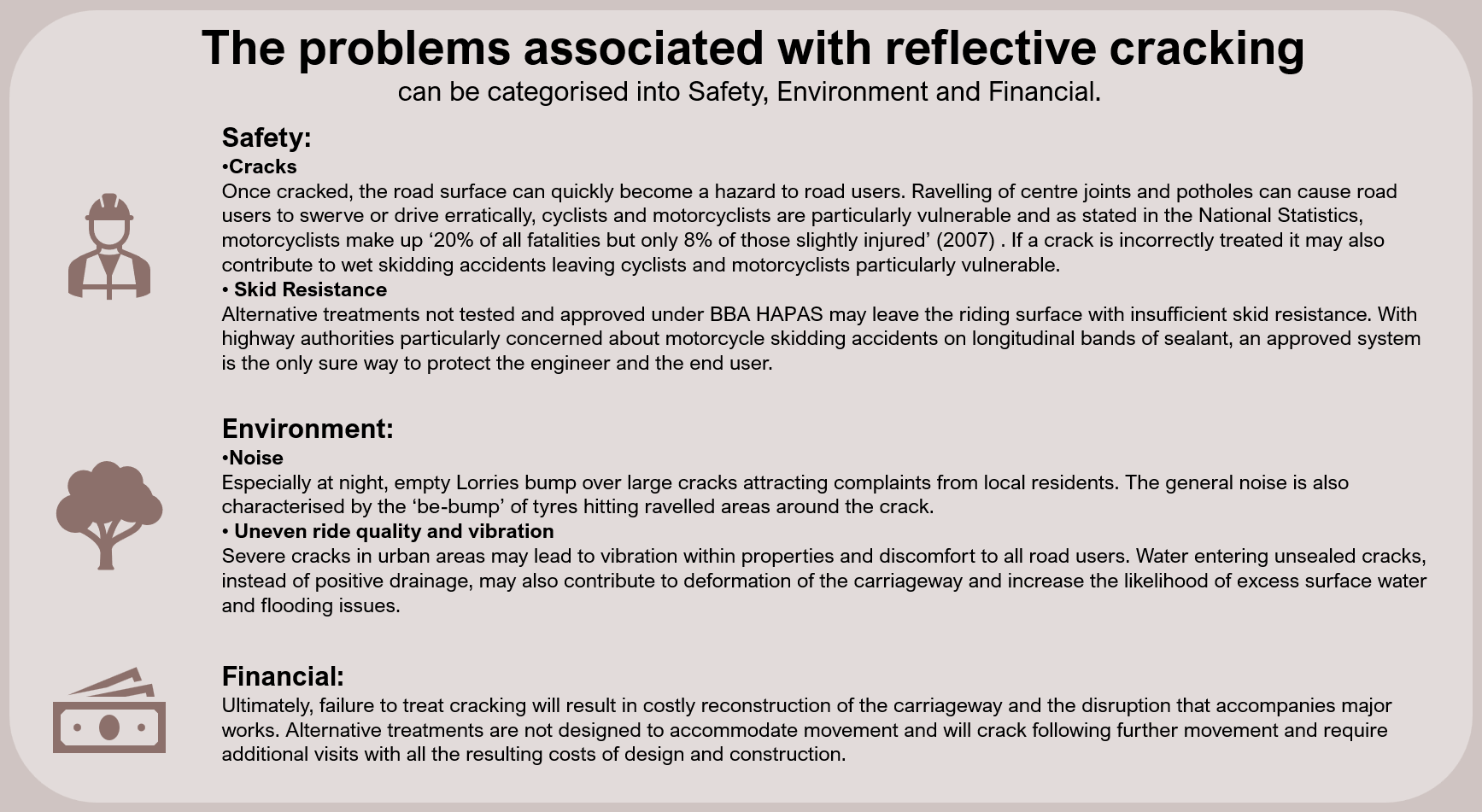

Despite millennia of technological advancement, engineers still face one of the oldest and most persistent challenges:

"How do I repair a cracked road surface?"

The answer, then as now, lies in one word:

Flexibility.

At Rhino, we bring this ancient principle into the modern age with Jointmaster®—a flexible, polymer-modified crack and joint repair system designed for today’s highways. Whether you're repairing asphalt or concrete, city streets or motorways, the goal remains the same: a durable, watertight, flexible repair that stands the test of time.

Jointmaster® – Designed for Performance. Approved for Compliance.

Jointmaster® is specifically engineered to combat reflective and fatigue cracking, offering a flexible, high-performance treatment system suited to even the most demanding highway environments.

Backed by independent approvals and delivered by certified professionals, Jointmaster® offers unmatched technical assurance:

✅ BBA-HAPAS approved under the Highway Authorities Product Approval Scheme (HAPAS)

✅ Fully compliant with Clause 711, Volume 1 of the Manual of Contract Documents for Highway Works (MCHW)

✅ Installed exclusively by Rhino—certified to:

ISO 9001:2015 (Quality Management)

ISO 14001:2015 (Environmental Management)

ISO 45001:2018 (Occupational Health & Safety)

Trusted across the UK, Jointmaster® is the market leader in crack repair systems and is the preferred solution on the majority of Highways Agency motorway and trunk road contracts.

Typical crack

How can Jointmaster help?

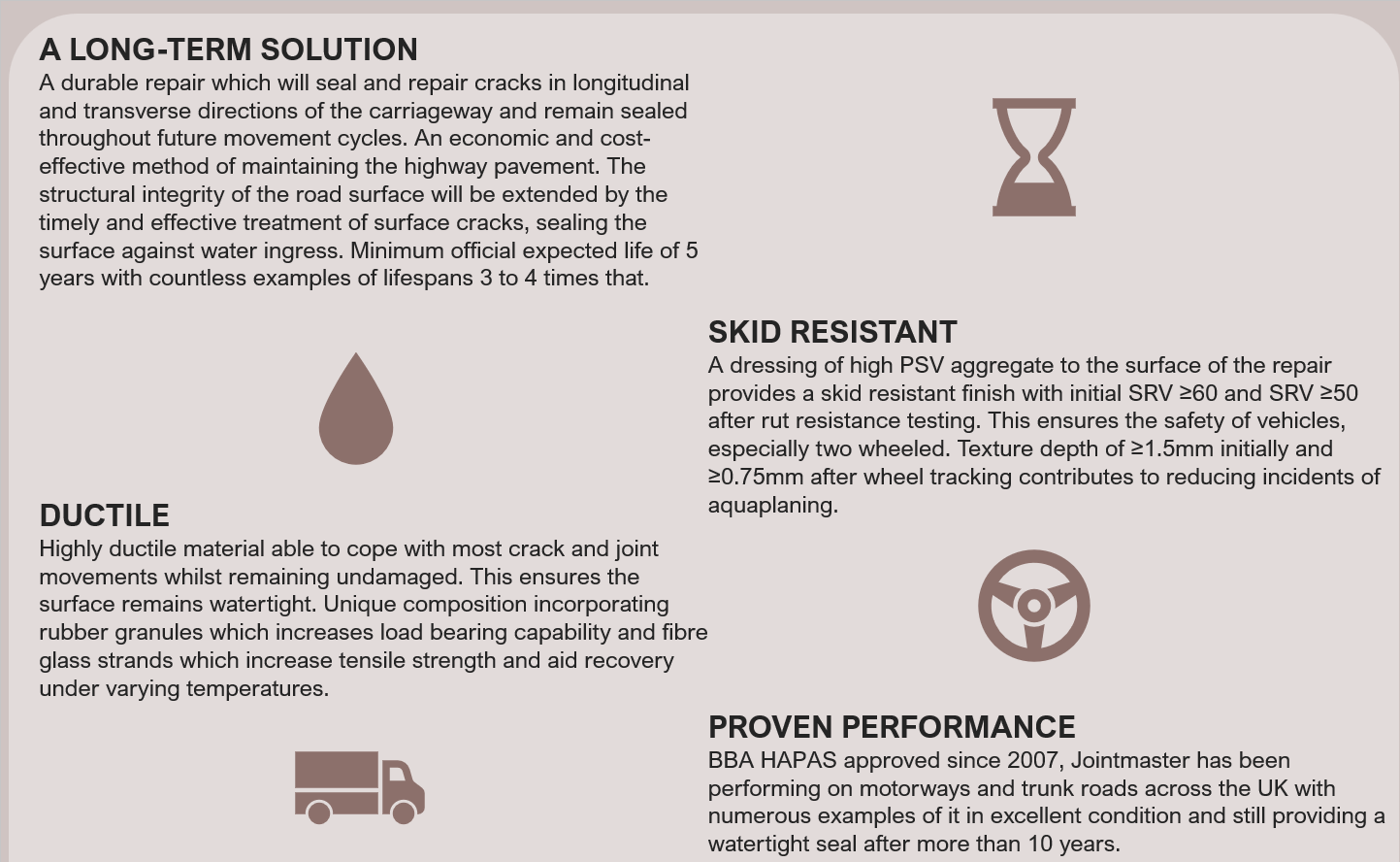

Jointmaster® was purpose-built to meet the exacting standards of the BBA HAPAS specification for flexible inlaid crack repairs—delivering long-term performance where it matters most.

Engineered for Movement, Built for Strength

The system is formulated to:

Flex with the carriageway – absorbing thermal expansion, contraction, and load-induced movement

Bond tightly to the surrounding surface – ensuring durability under traffic stress

Resist modern-day traffic loads – including HGVs, buses, and repeated wheel tracking

Jointmaster’s composition includes:

Polymer-modified rubber/bitumen binder

Graded granite aggregate

Mineral fillers

Chopped synthetic fibres

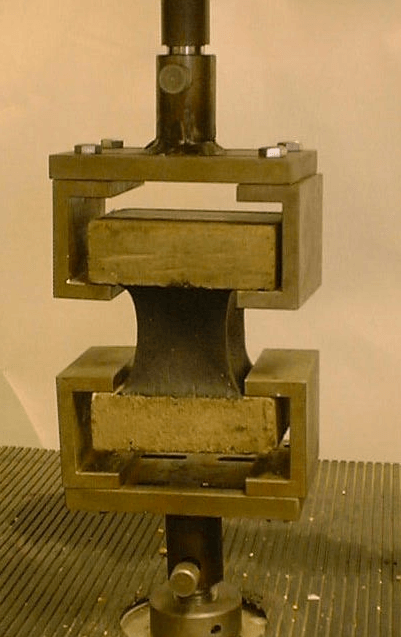

This combination allows the material to stretch and compress without cracking or tearing. BBA HAPAS testing confirms elongation performance exceeding 30%, while maintaining high skid resistance even under heavy trafficking.

Protecting Pavements, Prolonging Life

By sealing the crack and preventing water ingress, Jointmaster® reduces the risk of further deterioration, extending the serviceable life of the pavement and delaying the need for more expensive resurfacing or reconstruction.

Flexibility of Jointmaster binder being tested

Our newest edition to our planer fleet

BBA HAPAS: Meeting the Standards That Matter

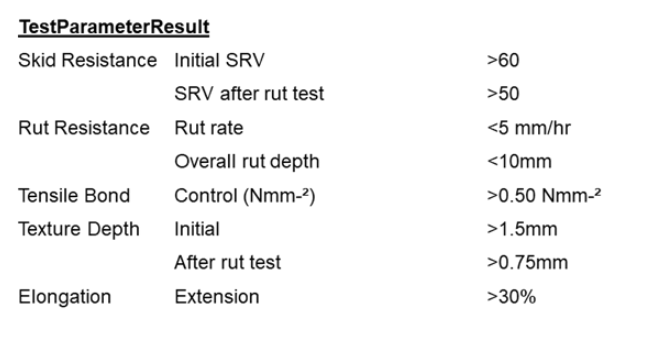

To achieve BBA HAPAS approval, inlaid crack repair systems like Jointmaster® must undergo rigorous, independently verified testing. These criteria were developed in consultation with the Highways Agency to ensure products are fit for use on the UK’s most demanding road networks.

✅ Skid Resistance Testing

Skid resistance must be proven both before and after wheel tracking simulation.

This was a key requirement from the Highways Agency, specifically aimed at reducing motorcycle skidding incidents on longitudinal joints and crack repairs.

✅ Rutting Resistance

Materials must demonstrate adequate structural strength to support adjacent surfacing.

Without this, the repaired area could become a weak spot, triggering early rutting or deformation under traffic loading.

✅ Tensile Bond Strength

This test measures the product’s ability to adhere to the surrounding road surface.

A repair that resists internal cracking is of little use if it debonds at the edges—which is why high bond strength is essential to long-term performance.

✅ Elongation (Flexibility)

Arguably the most crucial test for inlaid repairs under Type F (Flexible) classification. The material must elongate to at least +30% of its original width under tension, without cracking or separating.

This ensures the repair can accommodate ongoing road movement—a critical factor in the fight against reflective and fatigue cracking.

In contrast, Type H (Hard/High Modulus) systems are not required to meet this elongation standard, making Jointmaster®’s flexibility a key differentiator in durability and performance.

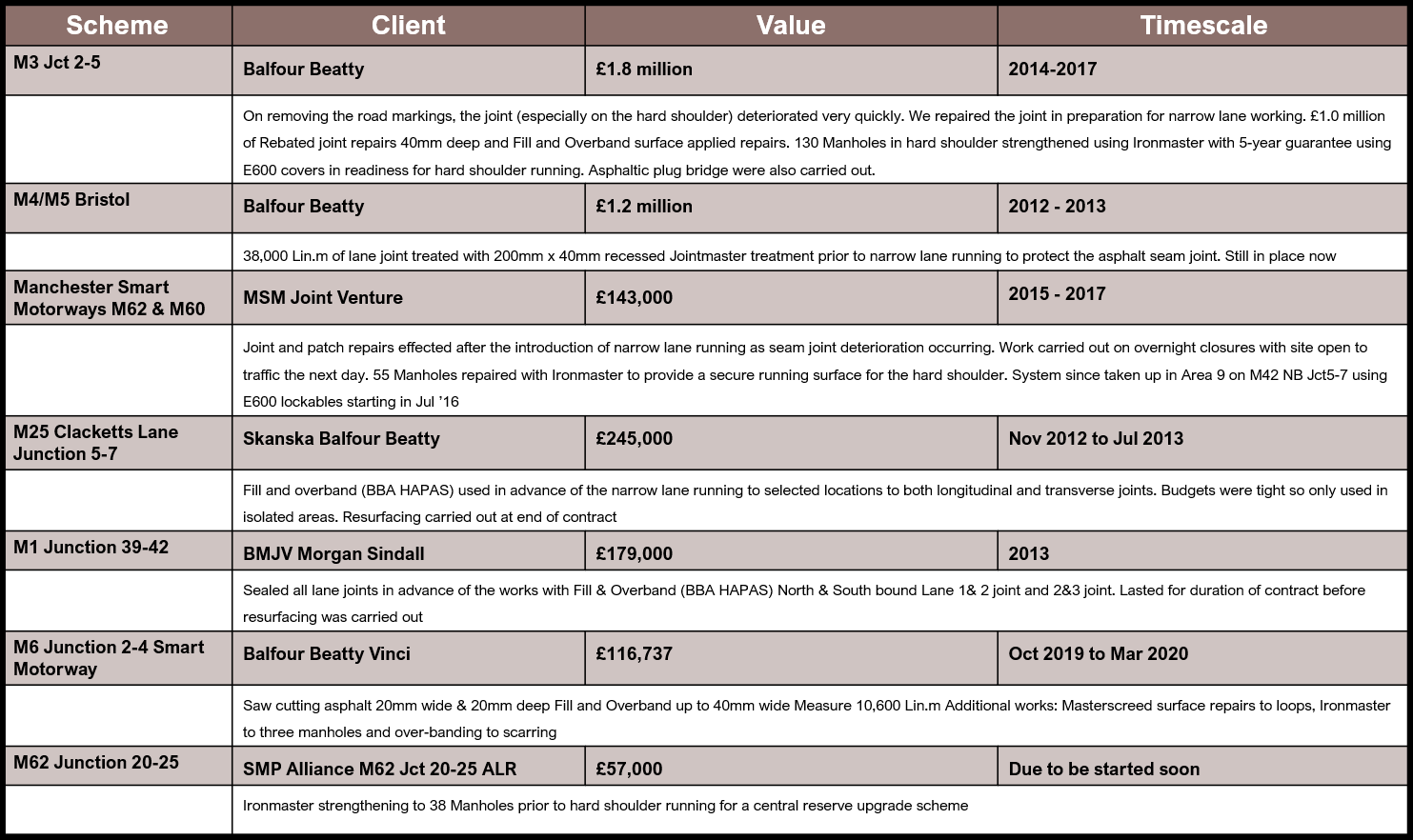

Our Jointing and Ironwork system are BBA HAPAS approved and are in use on: 6 Smart Motorway schemes (to the value of £3.6 million), 13 Super Agency areas, Scottish Motorways, DBFO schemes, Transport for London, 70 Local Authorities, and a handful of airfields and runways.

Why are we the preferred supplier for Crack & Joint Repairs

At Rhino, we combine decades of specialist experience, certified solutions, and a deep understanding of highway network demands to deliver joint and crack repairs that are fast, durable, and cost-effective.

Proven Performance, Trusted Nationwide

Over 1 million linear metres of joints repaired on UK roads

Products regularly specified on National Highways contracts, with £12 million+ of value delivered in the last 10 years

Used and trusted by Local Authorities, Tier 1 contractors, and strategic highways partners across the UK

Specialist Systems, Independently Approved

Full range of BBA HAPAS-certified treatments, including:

Overbanding

Fill & overband

Recessed repairs

Infill systems

We hold approval across every BBA HAPAS category—so we recommend the right solution, not just what we sell

Flexible-grade materials offering 30%+ elongation, absorbing future movement and preventing re-cracking

Decades of Expertise

Our leadership and site teams have been installing these systems since the early 1980s

We know the pitfalls, best-fit applications, and savings opportunities across every type of site

Early Involvement = Real Savings

We encourage Early Contractor Involvement (ECI) to understand your needs from the outset

This allows us to:

Reduce cost through value engineering

Minimise disruption through efficient programming

Accelerate delivery where needed

Our focus: Right-first-time repairs, completed on time and within target cost

Certified to the Highest Standards

ISO 9001:2015 – Quality Management

ISO 14001:2015 – Environmental Responsibility

ISO 45001:2018 – Health & Safety

CHAS Registered

Minimal Disruption to Road Users

Night-time working allows full daytime reopening of highways

Ideal for traffic-sensitive routes, urban centres, and motorways

Use on Motorways:

M4/M5 Bristol Case study

The three different combinations (all BBA HAPAS approved) for treating your cracks:

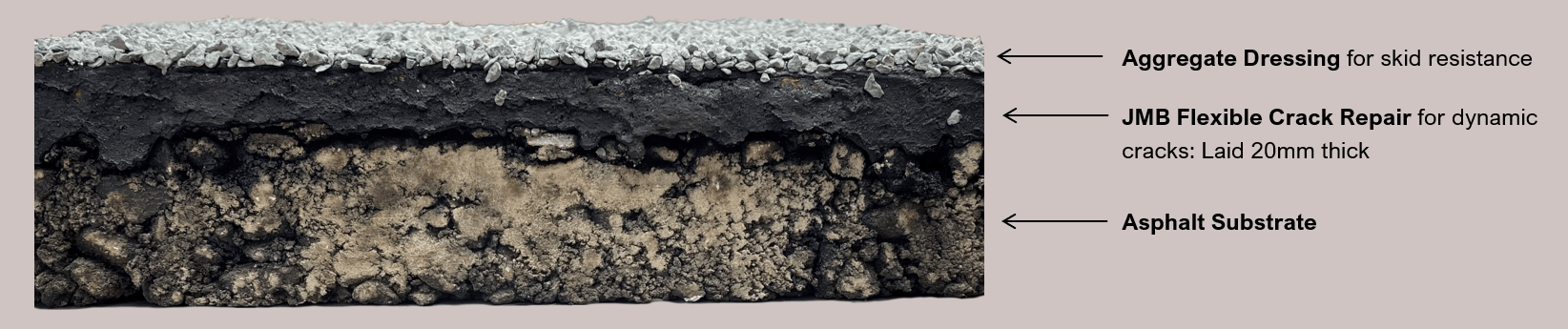

JMB Flexible Repair

Depth: 20mm deep material recessed into the surface

Width: Typically 200mm or 300mm wide to encompass all the defective material

Dressing: dressed with aggregate for a skid resistant finish

Features: Flexible material for dynamic crack repairs in low to medium density traffic areas (Type F)

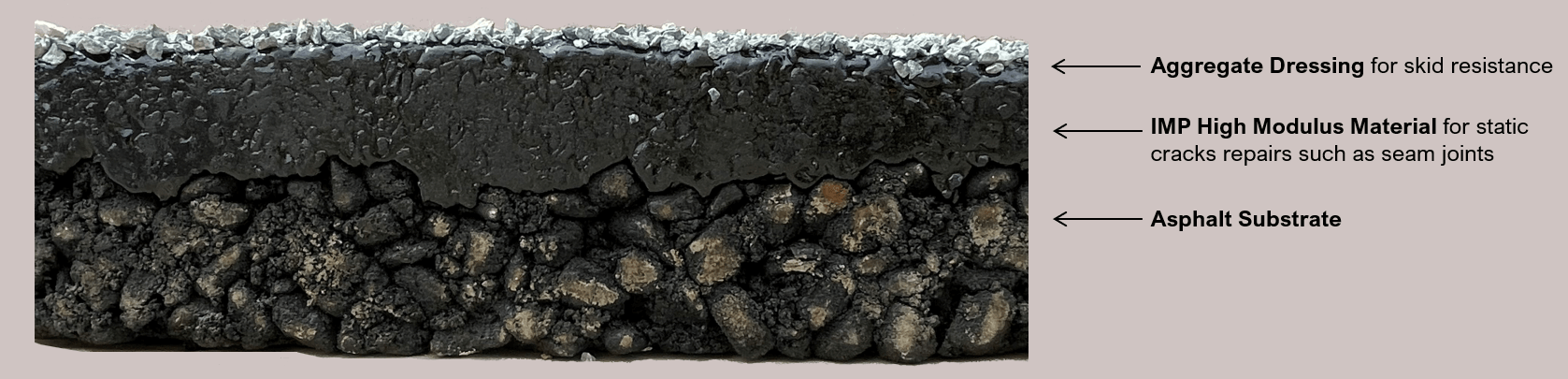

IMP High Modulus Repair

Depth: 40mm deep material recessed into the surface

Width: Typically 200mm or 300mm and up to 500mm wide to encompass all the defective material

Dressing: dressed with aggregate for a skid resistant finish

Features: High modulus material for static cracks such as seam joint repairs in low to high density traffic areas (Type H)

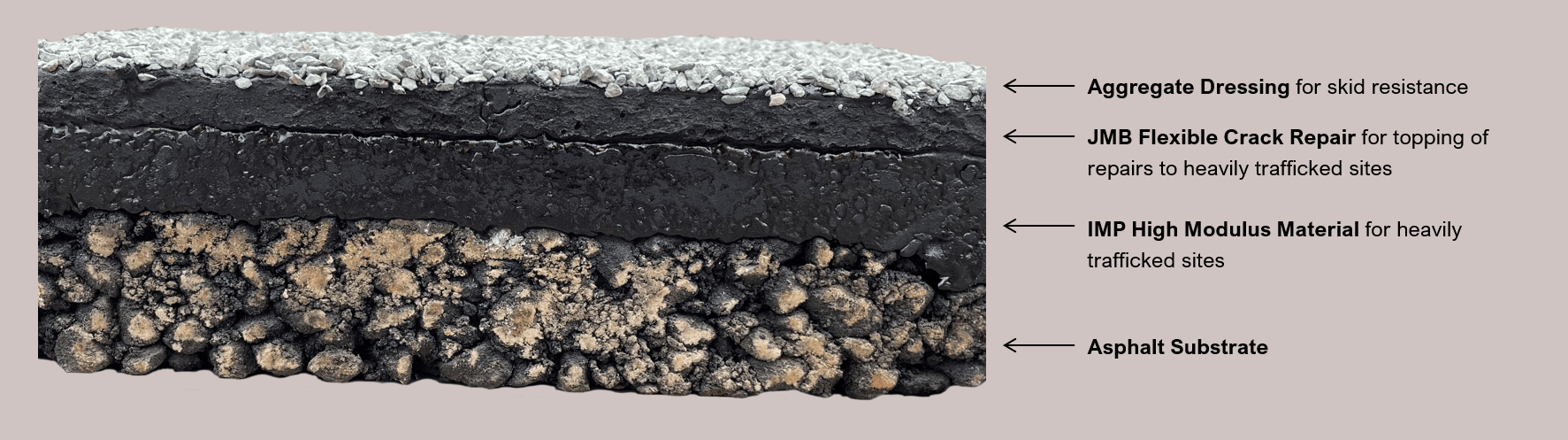

IMP base layer combined with JMP top layer

Depth: From 40mm deep recessed into the surface up to 100mm deep depending on existing deterioration

Width: Typically 200mm or 300mm and up to 500mm wide to encompass all the defective material

Dressing: dressed with aggregate for a skid resistant finish

Features: High modulus IMP (Type H) material in the base with a top layer of JMP Flexible (Type F) for dynamic cracks in high traffic density areas, Bus Lanes, HGV’s, Motorways & Trunk Roads.