BBA HAPAS Certification

- Cracks

BBA HAPAS Certification

Crack Sealing Systems You Can Trust

While BBA HAPAS certification is well established across the UK for High Friction Surfacing, its role in crack and joint sealing is equally important—but often overlooked.

Why Regulate Crack Sealing?

Before 1999, crack sealing was largely unregulated. Overbanding systems varied significantly in quality and safety. Of particular concern were:

- Excessively wide, smooth overbands

- Low-quality bituminous binders with poor skid resistance

- Increased skid risks for motorcycles and cyclists

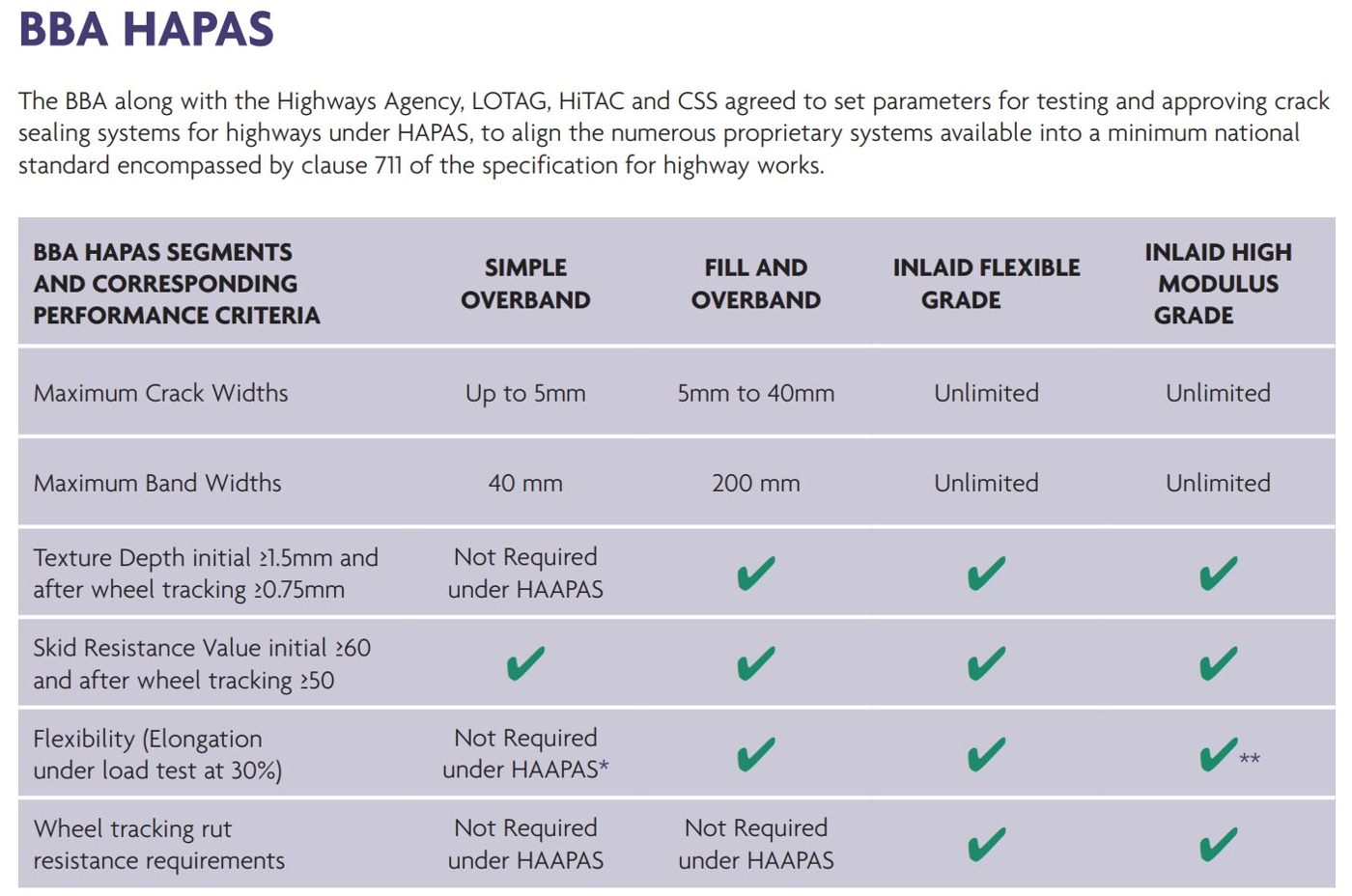

Recognising the safety risks, the BBA created Specialist Group 2 under the HAPAS scheme—specifically to assess, test, and approve crack sealing systems used on the UK road network.

Crack sealing became only the second highway treatment to receive a dedicated BBA HAPAS specialist group—underlining its importance to road safety.

What Does the Standard Say?

Crack sealing is not optional—it’s embedded in official UK guidance and specifications:

- DMRB (HD31/94) states:

“Crack sealing is carried out to extend the useful life of the road pavement by protecting the edges of cracks and joints from attrition by heavy traffic and by preventing the ingress of water.” - Specification for Highway Works, Series 700, Clause 711 requires:

“Over-banding and inlaid crack sealing systems shall have current BBA HAPAS Certificates.”

This clause also mandates that all new systems meet minimum skid resistance levels of 60 SRV, to protect vulnerable road users.

Where Does That Leave Us?

More than a decade after these rules were established, not all crack sealing on the network is compliant—but where approved systems have been used, the result is a significantly safer, longer-lasting road network.

Certification isn't red tape—it's a safeguard. And it's essential for protecting road users and your investment in the asset.

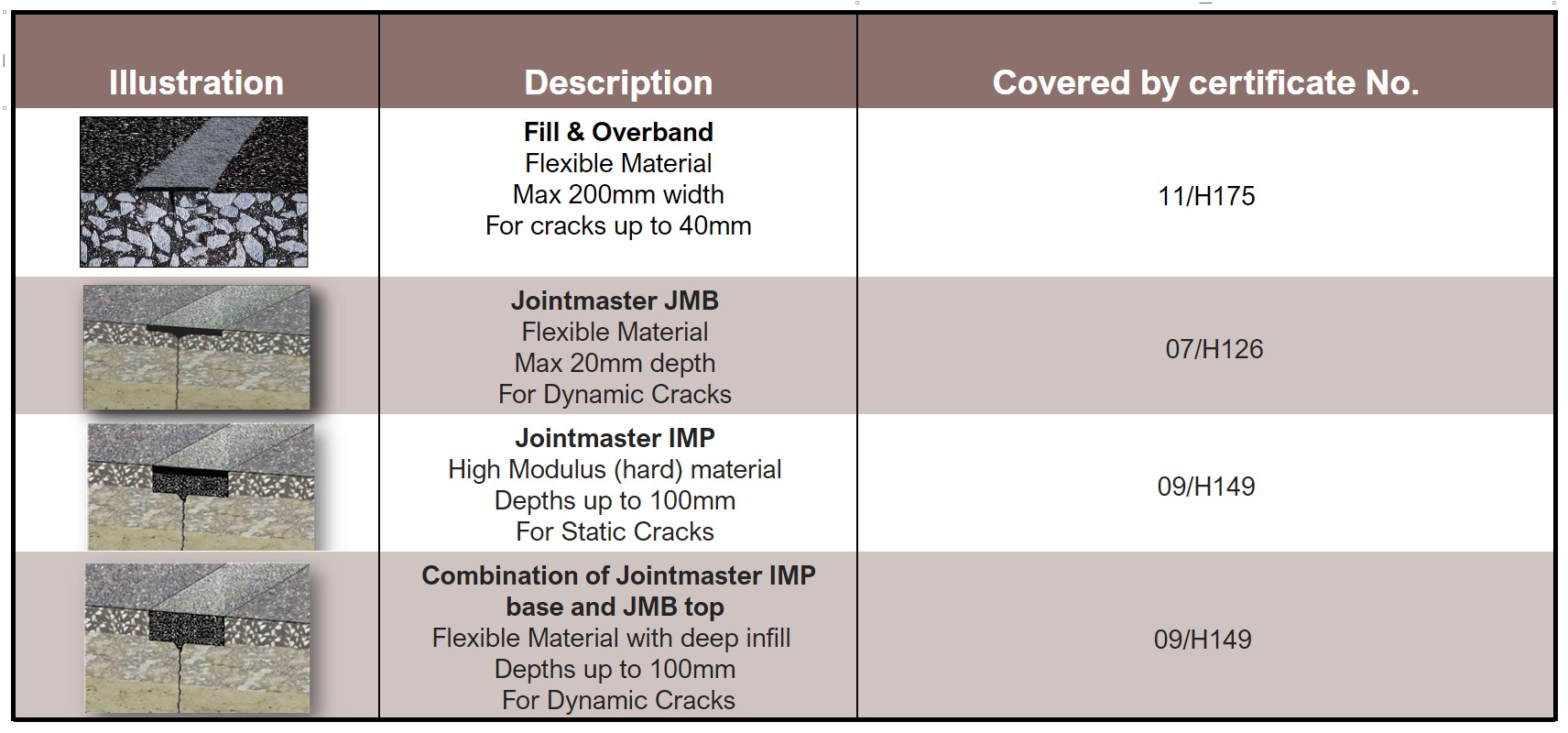

Certified Solutions from Rhino

Rhino Asphalt Solutions offers three fully BBA HAPAS-approved systems for crack and joint sealing—designed to meet the needs of both routine maintenance and high-spec motorway applications.

We help highways engineers ensure:

- Full compliance with SHW Clause 711

- Excellent skid resistance for safety

- Long-term durability and watertight sealing

With Rhino, there's an approved system for every scenario—giving you peace of mind and a compliant, high-performing result.

Rhino's crack and joint repair BBA HAPAS certificates

BBA HAPAS Certificate 11/H175

BBA HAPAS Certificate 07/H126

BBA HAPAS Certificate 09/H149

Jointmaster IMP (grade H) inlaid crack sealing system for highways

Jointmaster JMB flexible inlaid crack sealing system for highways

Ultraband

Fill & Overband System

Joint Repair Systems approved under BBA HAPAS