Main Features of Ironmaster

Main Features of Ironmaster

What makes Ironmaster different?

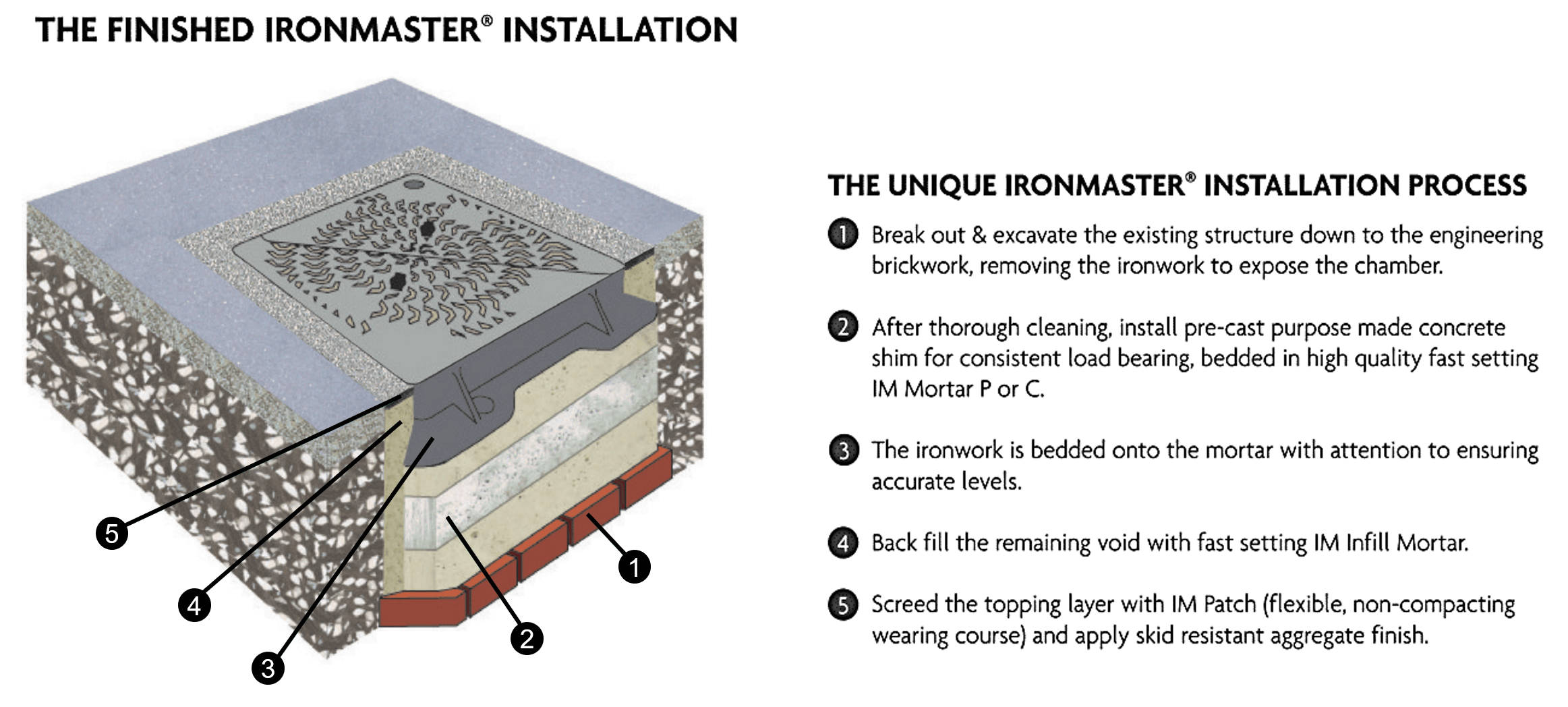

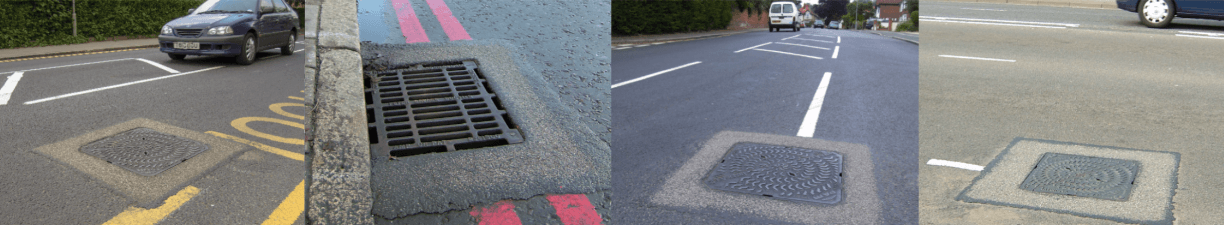

Ironmaster is a premium, engineered solution for ironwork reinstatement, installed exclusively by our own specialist crews. It uses high-strength, rapid-setting materials—including a unique, compaction-free surface course—to deliver robust, repeatable performance. This system underpins our exclusive 5-year written guarantee, offering unrivalled assurance in the sector.

Versatile Application across Ironwork Types

Ironmaster is a highly adaptable system, capable of accommodating a wide range of ironwork installations, including:

- Stopcocks

- Fire Hydrants

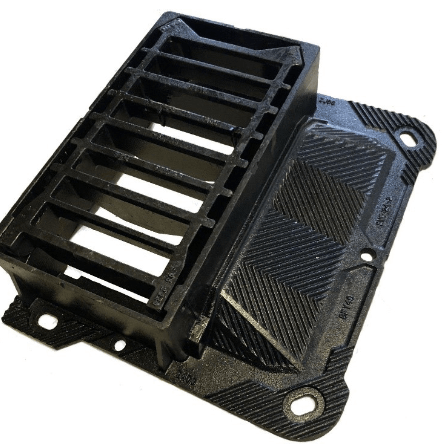

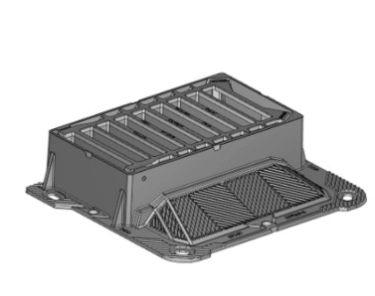

- Single and double gullies

- Manholes (single, double, and triple)

- 100mm or 150mm thick ironwork

- Bridge drainage channels

- Proteus narrow gully

- Modular multi-span units

The Ironmaster approach handles non-standard sizes, unexpected underground conditions, and surface deterioration without compromise—making it ideal for reactive and planned programmes alike.

Why Traditional Ironwork Repairs Fail

Most ironwork failures stem from three recurring issues:

✅ Inconsistent workmanship:

Our Ironmaster crews are trained and focused solely on delivering this system, with daily installations across the UK.

✅ Inferior or unsuitable materials:

Ironmaster is certified by the British Board of Agrément (BBA) under their BBA HAPAS scheme, ensuring proven performance.

✅ Poor asphalt compaction:

Our proprietary surface course requires no compaction, eliminating voids and structural damage—100% of the time.

Built on Research, Proven on the Road

Ironmaster isn’t just a product—it’s the result of extensive research into why ironwork fails. Every known failure mode has been studied and mitigated. The result: consistent durability, long-term structural integrity, and significantly fewer repeat interventions.

Whole-Llife Cost Savings

Ironmaster delivers measurable, long-term savings:

- Over £10 million saved by highway authorities by eliminating repeat ironwork repairs—particularly on principal routes and wheel track locations.

- Independent studies show traditional repairs often fail within 2½ years, while Ironmaster installations consistently outperform, backed by our 5-year written guarantee.

- With 10,000+ installations currently under warranty, Ironmaster has redefined value and performance for highway ironwork repair.

"Asset management is critical to our customers. We know that they must assess the long-term benefits on every investment and sometimes make rational decisions based on calculated assumptions – but at the end of the day, they are assumptions. These results confirm that the quality of the Ironmaster workmanship and the quality of materials used makes the 5-year guarantee a reality."

Specialist Focus: Manholes and Gullies

Manhole Replacement

Manholes degrade over time due to corrosion, ground movement, and general wear. This deterioration can pose risks to pedestrians, vehicles, and drainage systems. Replacing or reinstating ironwork with Ironmaster ensures:

- Structural integrity

- Enhanced road safety

- Seamless integration with modern drainage and utility access systems

How we repair and reinstate a manhole

Gully Upgrades

Gullies are vital to drainage. When blocked or degraded, they cause:

- Surface water flooding

- Erosion and watercourse pollution

- Infrastructure damage

Ironmaster enables effective gully reinstatement using modern materials and can be integrated into sustainable urban drainage systems (SuDS) to reduce environmental impact while enhancing system resilience.