High-Performance Materials Improve Ironwork Reinstatements

Material Performance

The long-term success of Ironmaster is built on the use of high-performance, BBA HAPAS-approved materials—each designed to withstand the rigours of UK highway environments. These materials form the foundation of our written 5-year performance guarantee.

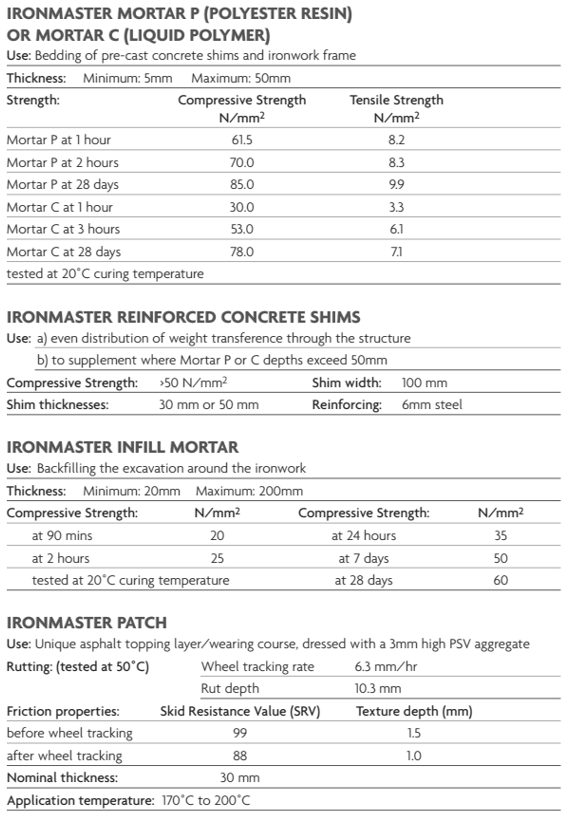

- Ironmaster Bedding Mortar

Reaches higher compressive strength in 1 hour than standard concrete achieves in 28 days. - Ironmaster Reinforced Concrete Shims

Engineered for exceptional compressive strength to resist extreme loading conditions. - Ironmaster Infill Mortar

Rapid curing properties enable early reopening to traffic without compromising performance. - Ironmaster Wearing Surface

Requires no compaction, eliminating voids and ensuring consistent long-term durability.

Technical Information

Ironmaster is a full-depth ironwork reinstatement system that eliminates the need for vibrating rollers or heavy compaction equipment. Its unique construction combines:

- A self-compacting, shock-absorbing surface course

- Rapid-set mortars that deliver early strength gains

- A joint-free design that minimises future crack propagation

The system is designed to be traffic-ready within 60 minutes, while providing structural performance that extends well beyond 60 months.

Ironmaster is compatible with:

- 100mm & 150mm thick ironwork

- Surface-mounted utility covers

- Modular and multi-span chamber systems

Installation Assurance

The performance of Ironmaster depends not just on materials, but on installation quality. All Rhino operatives are fully trained and certified in the Ironmaster system to ensure consistent, high-quality results—every time.

Better materials. Better process. Better performance.

That’s Ironmaster.